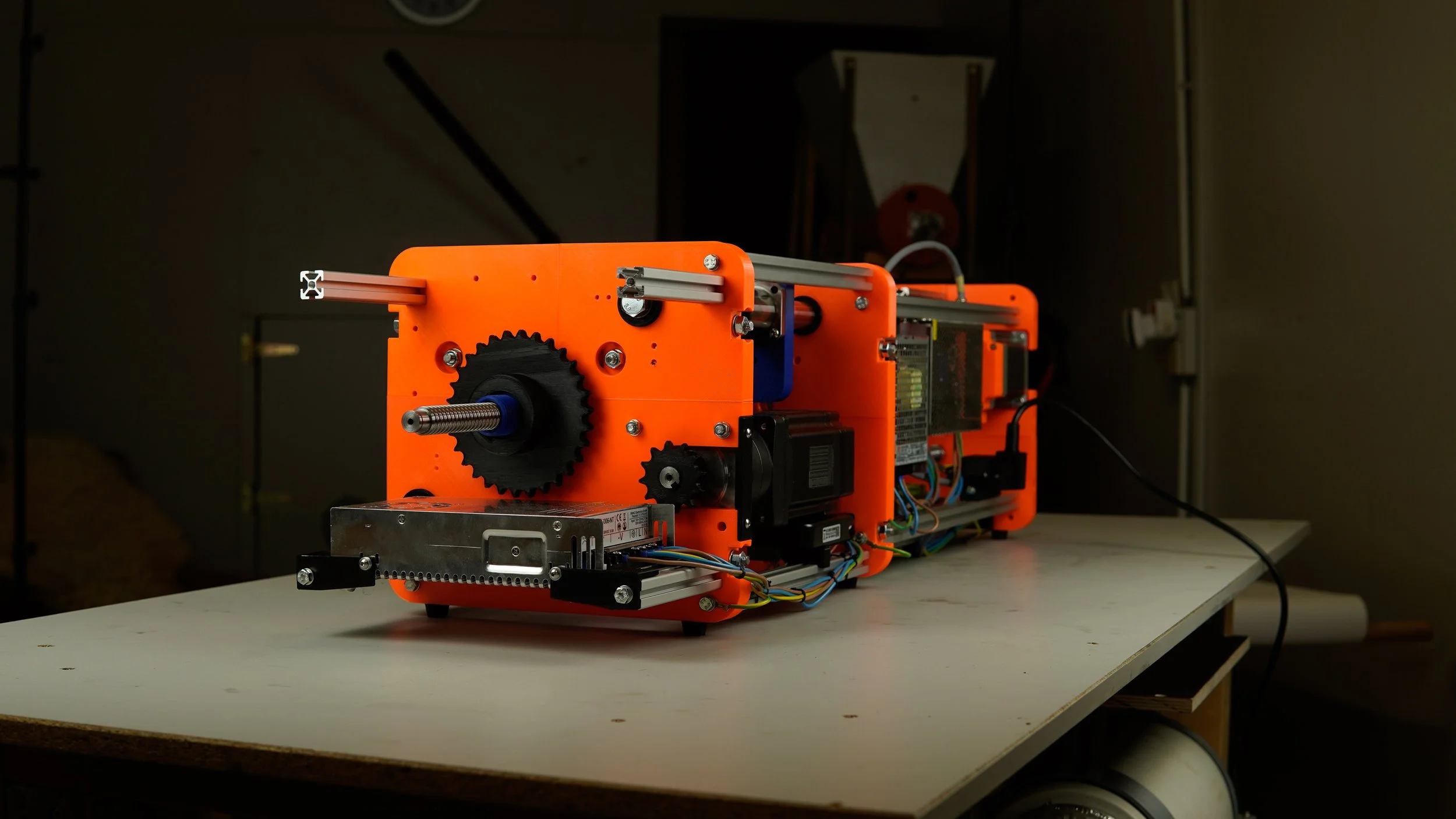

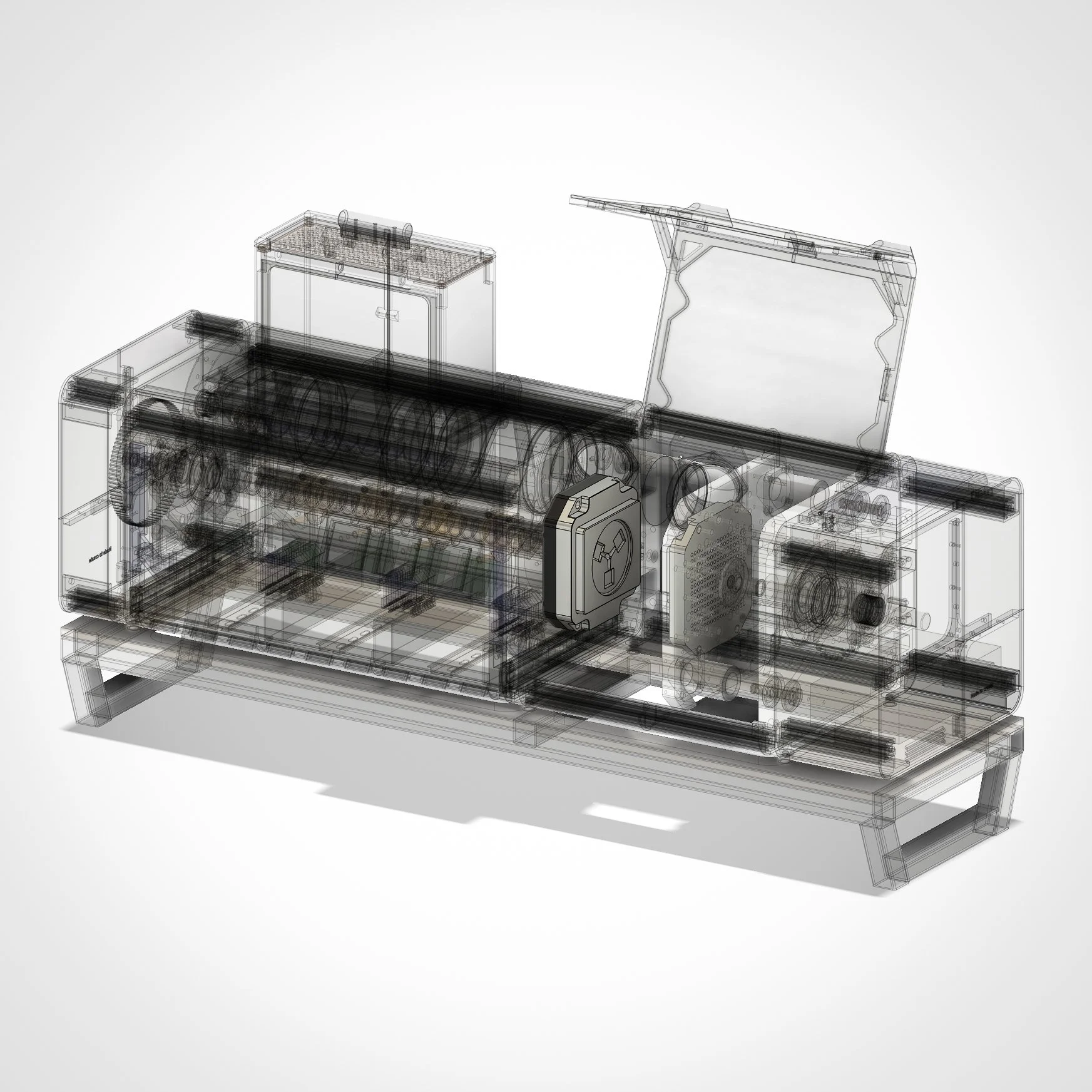

TARS (Tiny Automatic Recycling System)

TARS is a desktop injection molding machine designed to automatically recycle plastic waste. It fits on a tabletop and quickly transforms plastic waste into useful new items.

Products

Egg Cups molded from plant pots

A waste product in brown and red tones, becomes a new iteam for everyday use.

AirTag Keychains out of cream cups

What once contained cream for cooking, now keeps the AirTag on your keys.

Wall hooks made of polypropylene waste

Plastic waste transformed into functional design for home and workshop.

Molds

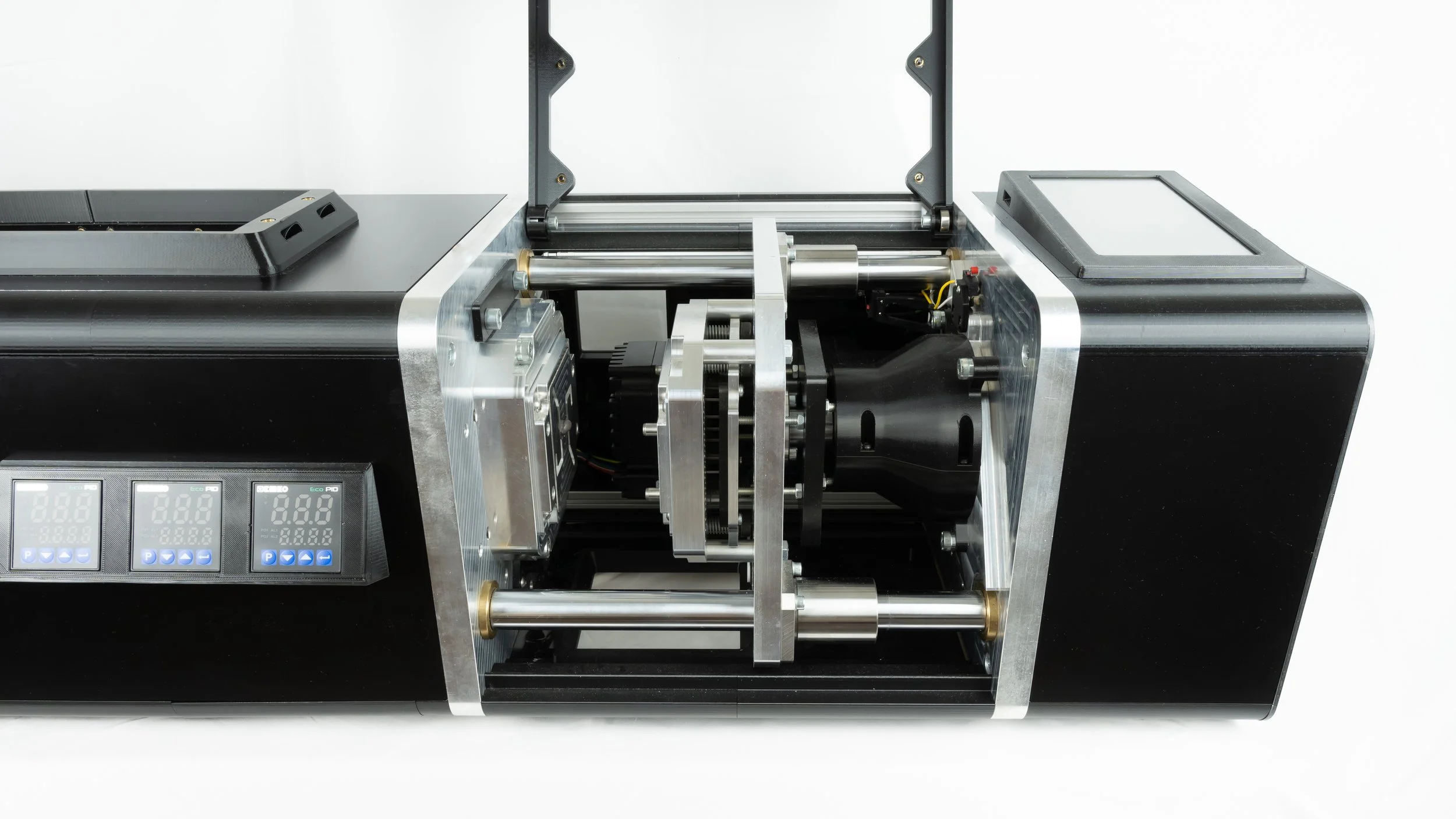

Aluminum molds for mid-volume production

Durable tooling for consistent results and smooth part finishes.

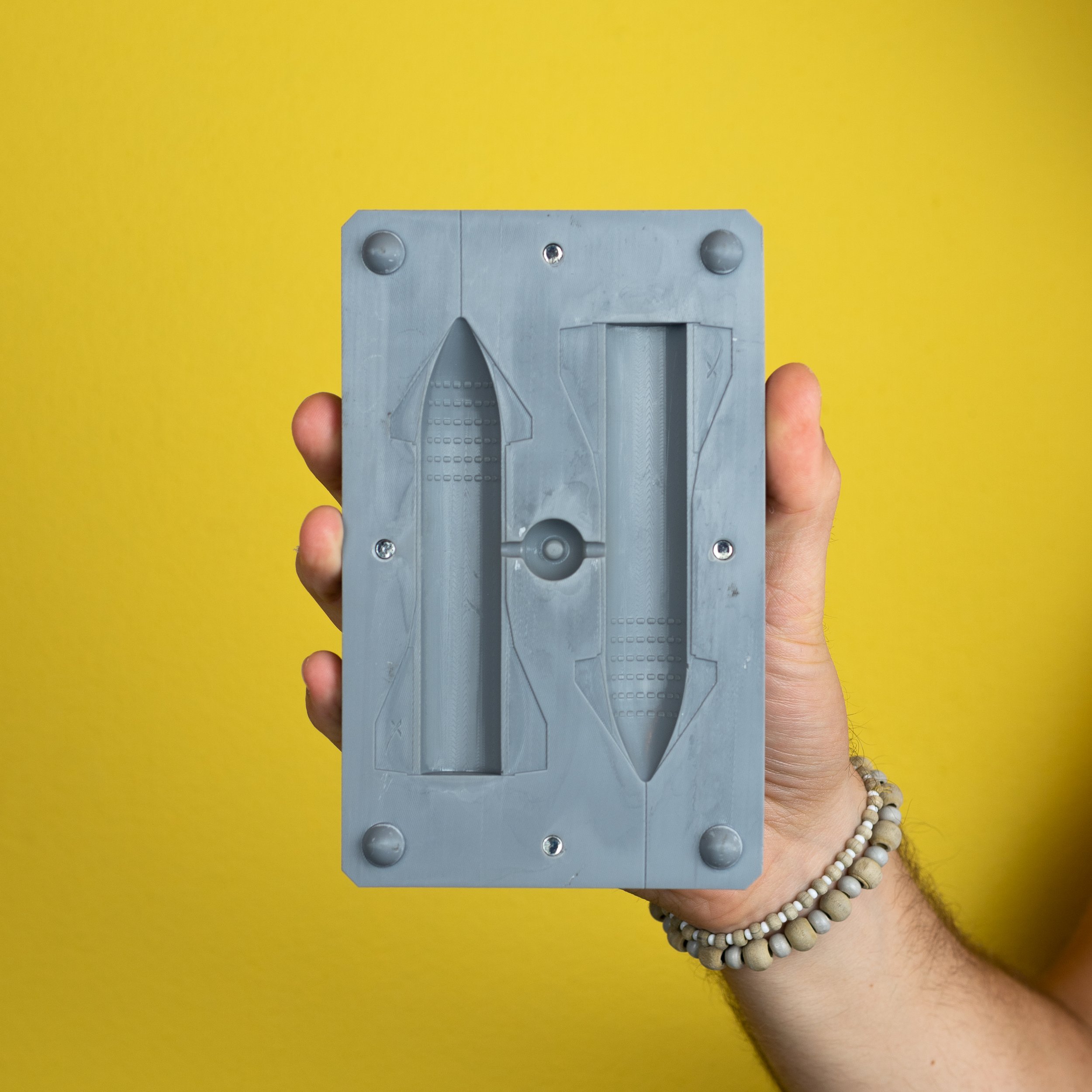

Resin molds for quick prototyping of ideas

Fast, flexible, and ideal for testing new shapes before metal tooling.

Adaptable mold system

equipped with a multi unit box (MUB) that works as a standard socket for different molds (size 100 x 120 mm).

FAQs

-

TARS is a desktop-sized injection molding machine designed for plastic recycling and small-scale manufacturing. The goal is to give makers, engineers, and educators access to a compact machine that can turn recycled plastic or pellets into new parts. It is still in active development but already capable of producing functional prototypes and small plastic products.

-

TARS is still in active development and not available for sale yet. We are building and testing prototypes to make the system reliable and user friendly. Once the machine reaches a stable stage I plan to do test runs together with makerspaces, fablabs, and other educational institutions before offering it more widely. Updates on availability will be shared on my YouTube channel and Instagram.

-

The goal is to make TARS a compact and affordable injection molding machine that helps recycle plastic into new useful parts. I will continue developing hardware, software, and documentation. Once the machine is functional and tested I plan to share it with selected partners and later make it more broadly available, either through kits, small production runs, or other formats. If my plan to manufacture this machine does not succeed, I can still share the project as open source, similar to other projects I have released in the past.

-

Right now the estimated cost will be in the range of 7 000,- to 10 000,- EUR. It is difficult to be more precise since the prototype is still evolving and materials, machining, and electronics affect the final cost. The vision is to keep it as accessible as possible compared to existing industrial machines so that individuals, makerspaces, and small labs can afford it.

-

TARS is not open source at this point. I keep all rights reserved and hold the intellectual property for the machine. However, I openly share a lot of information about the functionality, components, and progress of the project to inspire and involve the community.

-

The best way to help right now is to follow the project, share feedback, and spread the word. Watching and commenting on videos, joining discussions, or supporting via Patreon or Ko-Fi all push the development forward. If you are an engineer, work in marketing, or have any skills or ideas that could help this project grow, feel free to reach out via the contact tab. Please include a short note about your background and how you think you could contribute.

-

TARS can currently mold products up to about 40 grams in polypropylene. Smaller parts are not a problem. Tested molds include a phone cover mold.

-

Large parts above ~40 grams will be difficult or impossible to produce on TARS. The machine is intended for small-scale items and prototyping.

-

Yes, TARS can process pellets. First tests with pellets were promising, but I still need to do more testing to make it reliable for different types of pellets. The goal is for TARS to handle both shredded recycled plastic and standard pellets so it is as flexible as possible.

-

Yes, there is a preliminary datasheet available in the TARS tab here on the website. Please note that the data is still early and should be taken with a grain of salt. Some of the test results, especially with different materials, still need further validation. As development continues I plan to release a more complete and reliable datasheet with detailed specifications and performance data.

-

TARS is still in development, so all specifications are preliminary and may change. Current data can be found in the preliminary datasheet in the TARS tab on this website. At the moment:

Shot weight: up to ~40 g (tested with polypropylene)

Materials tested: PP and PET (more materials to follow)

Heating system: electric cartridge heaters

Drive system: stepper-motor-driven injection unit

Machine size: desktop footprint

Power supply: standard mains power

Please note that these values are from prototype testing and should be taken with caution until further validation is done.

-

TARS runs on a single-phase 230 V power supply. The average power consumption is around 600 W or less, making it easy to operate in standard workshop or educational environments without any special electrical setup.

-

TARS is aimed at engineers, makerspaces, schools, universities, product developers, and recycling collectives. It is made for people and groups who want to work with an automatic desktop-sized machine for recycling plastics and creating prototypes.

-

There is currently no kit version planned. The first focus is on developing a fully functional and assembled version of the machine. A kit version might be considered in the future, but at the moment it is not part of the roadmap.

-

If you check out my Instagram or YouTube channel you can already see some of the products made with TARS. These include phone covers, AirTag mounts, wall pegs, and other items in a similar size and weight range. In general, parts up to about 40 grams are possible.

-

Resin molds have a shorter lifespan compared to aluminum molds. Still, the durability depends heavily on the geometry of the part. For example, the AirTag mold lasted for more than 100 shots. This shows that resin molds can be a useful and affordable option for certain applications.

-

TARS is much smaller and less powerful than an industrial injection molding machine. It is not in competition with large-scale equipment. Instead, it is designed to complement prototyping, small-batch production, and recycling research. Its purpose is to make injection molding and recycling more accessible on a desktop scale.

Still got questions?

If you have questions in regard to this project or another, feel free to reach out.