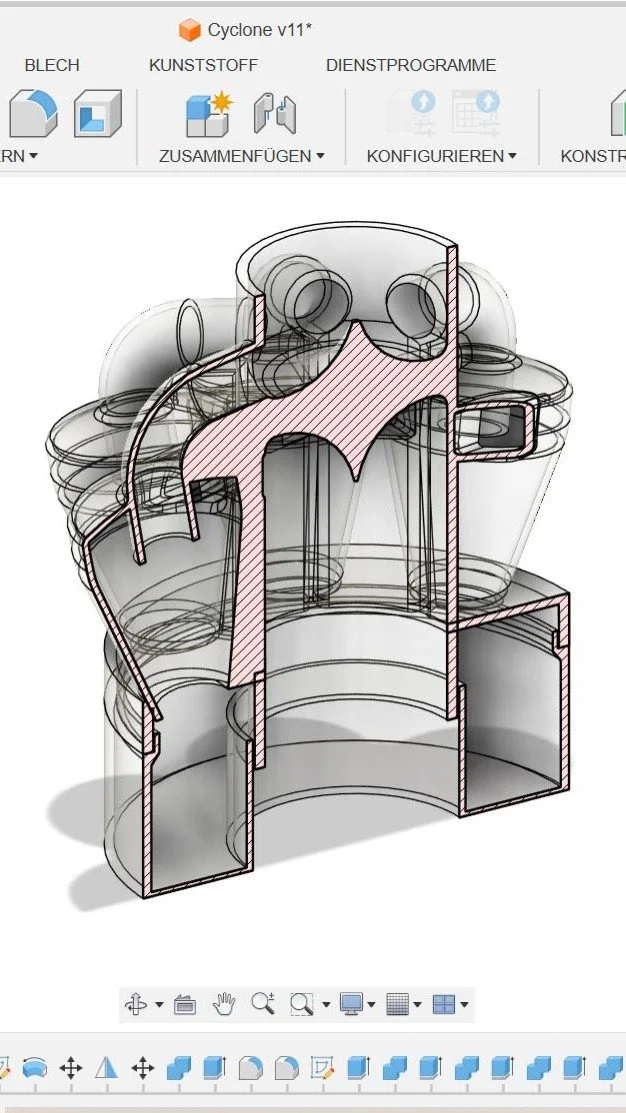

Cyclone separator

The 3D printed Cyclone Separator is a compact desktop unit designed to efficiently separate plastic dust and particles from the air during material transport processes. It fits on a tabletop and helps to separate particles from the airstream, that travels through, catching debris before it reaches the vacuum. It acts as a mechanical prefilter, improving my material transport and also extending the life of the vacuum bag.

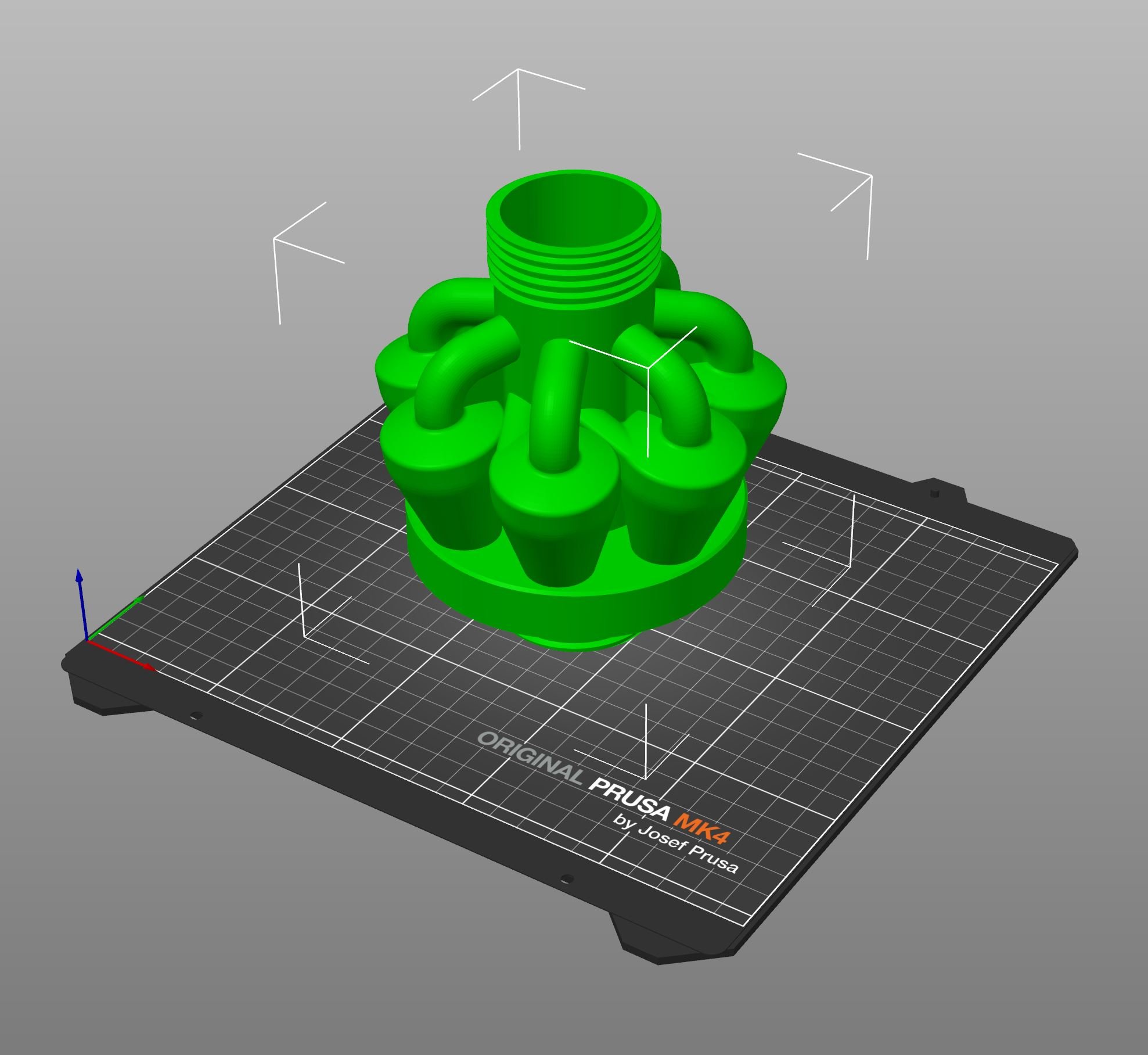

All 3D printed with screwable parts

Fully printable design. No glue, no fuss, just threads. Each part connects mechanically for easy assembly.

Adapt the files for your application

Modify, remix, and make it fit your own setup. Easy to adjust for different machines and workflows

A DIY project for material transport and filtering

Built for workshops, makers and hobbyists who value simplicity and functionality.

2-stage system for different particle sizes

Dual-stage cyclone for separating different particle sizes. Modular and easy to adapt with the CAD files.

Fits on the IKEA EKALTANT jar series

Designed for the IKEA EKALTANT jars, but also includes adapters for other containers in the full download kit.

Particle separation in action

The transparent jar shows how dust and chips are spun out of the air stream and neatly collected below.

Downloads

The Free Download Kit

Contains all the STL files to print the cyclone separator from the YouTube video. It does not contain any other CAD or info. More on that in the product description. (Publishing soon with the Cyclone YouTube Video)

The Full Download Kit

Contains all info you need to build, or adapt a separator to your own needs. With STL, CAD, Fusion files, Media, Infographics and a lot more.

FAQs

-

The Cyclone Separator is used to separate particles or materials from an airstream. It’s a compact solution for material transport and filtering, often used to collect plastic flakes, dust, or lightweight granules before they reach your vacuum or filter system.

-

No special tools are required. All printed parts are designed for the moste common FDM printers (Prusa MK3/MK4, Bambulab A1 etc.), and the assembly can be done with basic workshop tools such as screwdrivers and pliers. For melting the taped inserts a solder iron is needed.

-

On this page you’ll find direct links to the product files. In general, all Free versions are available on my Ko-fi, while the Full kits are available for Patreon supporters and also as single purchases on Ko-fi at the moment. I also share many project updates and new file releases on Patreon first.

-

No. The files are for personal use only. You’re welcome to print and modify the separator for yourself, but selling printed parts or remixed versions is not permitted without a separate commercial license.

-

The Free Download Kit contains all STL files featured in the video. Perfect if you just want to print and assemble your own separator.

The Full Download Kit includes everything from the free version plus additional CAD files, drawings, step-by-step documentation, and media assets that help you understand the system in depth or adapt it for your own setup. (The Full Download Kit is free for Patron Supporters or available as single purchase on Ko-Fi) -

It can be used as a pre-filter for small CNC machines or woodworking setups that rely on vacuums. It’s also great for 3D printing workshops that grind or shred plastic, small recycling systems, sanding stations, or any machine that generates dry dust or flakes.

Basically, anywhere you want to protect your vacuum from clogging or extend its filter life. -

Air and material enter the separator tangentially, creating a fast circular airflow. The heavier particles are pushed to the outer wall by centrifugal force and fall down into a collection container, while clean air exits through the top. This way, only air continues through the system, not the debris. More explanation is in the YouTube video on the device.

-

It’s made for dry materials only. Using it with liquids can reduce performance or damage printed parts.

-

Yes. The design uses standard hose diameters and can connect easily to most workshop vacuums, shredders, or granule systems. Also in both kits, there are different sizes of connector prints that work as an adapter for the tubing.

-

If you’re using the full kit, check the included documentation first. You can also reach out through the contact form on this website or follow me on Instagram and Ko-fi, where I regularly share updates and try to answer common questions.

-

No, there are files in the kits for 3d printing that work as the 1st dust chamber. You can print them and they will work as good as the jar for collecting particles.

-

The EKLATANT series from IKEA fits this cyclone. These containers are made of glass. Both the 0.8 liter glass and the 1.7 liter glass can be used. If these glasses are no longer available in the future, you can also 3D print a container using the file included in the kit.

Still got questions?

If you have questions in regard to this project or another, feel free to reach out.